Boiler Scale Inhibitor

Boiler Scale Inhibitor

Ion Exchange Resin on Sale

- info@bidragon.com

- +86-372-2190333

- +86-372-2190222

- +86 13213263322

+86 13213263002 - Whatsapp:+8613213263322

- +8613213263002

- Skype:hwbzzm

- Skype:bidragon2013

Professional Manufacturer for Boilr Scale Inhibitor

Professional Manufacturer for Boiler Water Treatment

BF-30A Boiler Anticorrosion Scale Inhibitor

1. Introduction for the technology

1. Introduction for the technology

1) The water boiler in the fields of industry and the people's lives, plays an important role. However, the operation corrosion, discontinuation corrosion and the scaling problems caused by the corrosion products in the water boiler system have been plaguing us for a long time. Because of the different working conditions between the water boiler and the steam boiler, as well as the simpler and cruder water boiler room than the steam boiler room, many effective technologies for the steam boiler are difficult to apply into the water boiler. Some technologies of anticorrosion scale inhibition in development for water boiler are not mature enough to apply. Some technologies are mature, but their applications are not common. These cases result in the serious corrosion in the water boiler currently. Even in foreign countries, this issue has not been solved yet. Generally, there will be significant metal corrosion, ferruginous discharges and leakage for the water boilers after the usage of 2~3 years. The water boiler corrosion is more serious in China. According to the statistics from the Liaoyang City Research Institution of Boiler, in Liaoning Province, there are 755 boilers is in corrosion, accounting for 95% of the inspected 800 heating boilers in use, in which severe corrosion is accounted for about 10% -15%; the corrosion leak about 5 % -8%. The normal maintenance cost for corrosion is nearly one million Yuan. The design life for our water boiler is about 15 years; while due to corrosion and other reasons, the boiler currently can only run for 5 to 8 years only accounted for 1/2 to 1/3 of the design life.

2)

Corrosions will cause huge economic losses. For water boilers, corrosions not only shorten the life expectancy of the boiler and significantly increase the maintenance costs, but also the corrosion leaks often occur in the heating period of the winter. The heating interrupt will directly affect the normal life of the residents. In order to change this situation, it is imperative to research and develop the technologies for anticorrosion scale inhibition for water boiler. Water boiler corrosion and its severe current situation have to do with the operation corrosion and discontinuation corrosion.

3)

In order to prevent the operation corrosion of the water boiler, for years, people are trying to apply the technologies of thermal oxygen, vacuum oxygen for steam boiler into the water boiler. But it turns out to fail, due to a lack of implementation conditions for the water boiler room. Specifically technologies for the water boiler, such as Desorption oxygen, REDOX resin oxygen, Arbiso process, Zincification, still have many problems to deal with. Arbiso process in high doses has been successfully applied in Japan, but this method is not commonly adopted by other countries, for the reason of the well-known toxicity as well as the reason that the insufficient dosage may cause boiler metal pitting.

4)

The discontinuation corrosion of the boiler is more serious than the operation corrosion. Corrosion and damage in a large scale and local corrosion and pitting are usually caused by the discontinuation corrosion. Water boiler system is in a short period of running and a long period of suspension. The ferruginous discharges and the leakage caused by the discontinuation corrosion occur frequently. In order to prevent or mitigate the discontinuation corrosion, some protection methods have been developed. The main methods are the traditional drying and wetting methods as well as the TH-901 method worked out in recent years. Under conditions of strict implementation, the traditional drying and wetting methods can achieve success. However, due to the complicated operation of the traditional methods, for the small and medium-sized boiler rooms are not always fully equipped with the implementation conditions and other reasons, the effect of the traditional method is far from ideal. TH-901 method with the efficient and convenient characters and long period of protection has been widely applied in the whole country, which is undoubtedly successful for the protection of the water boiler. However, for the complex pipe network, heat exchangers and household radiators of the water boiler system, it is difficult to protect for the reason that it is hard to place the TH-901 corrosion inhibitor on them. Because of the wide environment condition difference between the periods of operation and discontinuation, the operation corrosion and discontinuation corrosion still have some technology problems to solve as well. From the home and abroad recent research, development and application for anticorrosion scale inhibition of the water boiler or the individual technologies dealing with the discontinuation corrosion and operation corrosion separately have been the traditional mode. Therefore, it is necessary to research the effective and convenient discontinuation protection method for the water boiler system.

5)

With the acceleration of the urbanization and industrialization process in China, the heating system scale of the industrial boiler and the water boiler closely related with the production and living has also experienced the rapid growth. Due to the restrictions on the boiler water treatment technology and other reasons, the ubiquity of the scale and corrosion for the industrial boiler results in the loss of the life expectancy and increase of the maintenance and operating costs. Professor Wei Gang from Beijing University of Chemical Technology, titled with the "national outstanding experts", initiates the BF-30a boiler water treatment technology on the base of scale and corrosion rules for the industrial boilers as well as the principle of "synergy". This technology breaks through the processing mode of dealing with the operation and discontinuation corrosions separately; meanwhile this technology can solve the two problems about operation and discontinuation corrosions of the boiler and the heating system.

2. Technique Principle

1)Anticorrosion mechanism

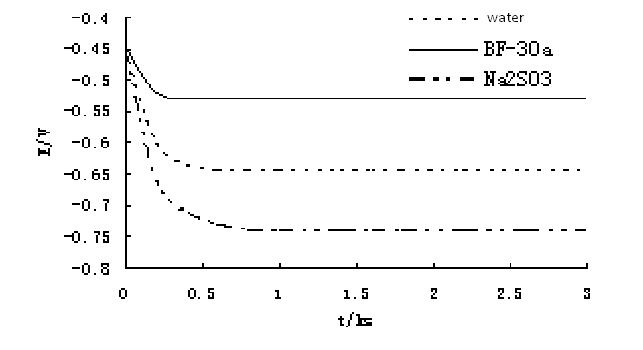

The anticorrosion mechanism of technology BF-30a is to generate a protective film on the boiler metal surface, which can be confirmed by the electrochemical tests.

Figure 1--- Effect of the additives on the electrode potential of 20g steel

From the steel electric potential - time curves (Figure 1), under the different conditions, the steel electrode potential experiences the first severe drop and then the stable process with time changing. I.E. firstly, the surface natural protective film destructs, and then the corrosion of the substrate take place. Contrary to the sharp drop of the steel electric potential after the adding of the oxygen scavenger such as sodium sulfite, the steel electric potential after the adding of the BF-30a remains a stable value after a little drop. This value is higher than the steel electric potential value in the water. The possible explanation is that the BF-30a has a significantly suppression to the anodic process.

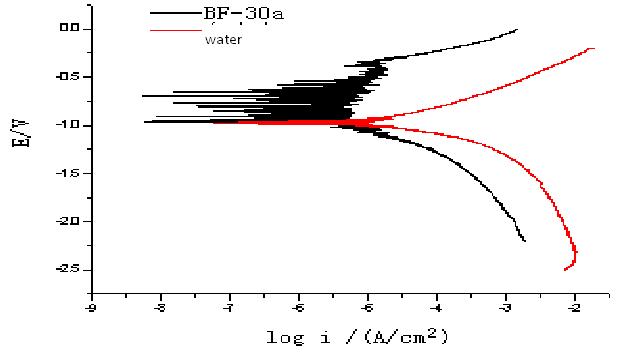

Figure 2 --- Potentiodynamic polarization curve for the steel in water

Figure 2 shows the influence of the BF-30a on the anodic process and the cathodic process for the steel corrosion in water. The BF-30a makes a drastic positive shift of the corrosion potential and a drastic increase of the anodic polarization. But from the cathodic polarization curves, although the BF-30a makes the oxygen ions potential decrease, the cathodic polarization increases significantly. Thus the BF-30a not only strongly inhibits the anodic process of steel corrosion, but also significantly inhibits the cathodic of the corrosion. It is a mixed inhibitor of steel in water. At the same time, the electrochemical test results are the good evidence to show the high inhibition efficiency of the BF-30a.

3. Scale Inhibition Mechanism

(1)

Chelating dissolution

1) The chelating agent can form a stable water-soluble chelate with the calcium ion in water, so that the hard components in water are in the dissolving state. The typical chelating agent is the ethylene diamine tetra-acetate (EDTA) and the nitrilo tri-acetate (NTA), whose inhibition mechanism is the chelating agent in reaction with calcium ion to blockade the scale cation in its molecule and to prevent the combination between the scale cation and the scale anion. By this way, a large number of calcium ions are left in water; the solubility of the micro-insoluble calcium in water increases, so that the calcium in the boiler is in the dissolve state. This chelating agent plays the role as a scale inhibitor. The chemical reaction runs according the stoichiometry: the hard components like calcium in the 1 mg of CaCO3 / L of requires 3.8 mg / L EDTA tetrasodium.

2)

In order to identify the chelating dissolution of BF-30a, it takes the similar test method as the chelant. Put the scale of calcium carbonate solids and calcium sulfate solids into the solution of BF-30a for the chelating dissolution test. The test results show that the concentration of the calcium ions increase slowly; that means that the BF-30a is with the moderate chelating ability to dissolve the scale. The main differences between the BF-30a and the EDTA: 1. EDTA reacts with the calcium ions according to the stoichiometry; while the chelating dissolution of the BF-30a for the calcium ions is not according to the stoichiometry; even in theory, it achieves the stoichiometric value; the chelation is still exit in the BF-30a. 2. Compared with the strong chelation of the EDTA, BF-30a dissolves the calcium ion gradually from the solid mildly. In many experiments, there are no the phenomena of scale block splitting and spalling. These characters are very important for the operation of the boiler. Because the chelating dissolution is to remove the scale in the boiler to restore a clean surface; but if there are the phenomena of scale block splitting and spalling, it is possible to cause the scale block blocking the pipeline.

(2) Lattice distortion

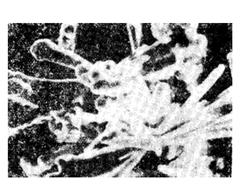

Figure 3--- the calcium carbonate scale without scale inhibitor

Figure 4--- the calcium carbonate scale with scale inhibitor

In order to identify the inhibition mechanism of the BF-30, observe the morphologies of the calcium carbonate particles with and without BF-30a by transmission electron microscopy. As the figure 3 and 4 shows that the calcium carbonate particles without BF-30a will generate the inerratic calcite crystals on the heat transfer surface; while when the calcium carbonate particles is with BF-30a, there is only a small amount of loose amorphous calcium carbonate in the heat transfer surface, which can easily be washed out by the water. Obviously, the BF-30a changes the crystallization type of calcium carbonate and inhibits the crystal of the calcite.

The crystallization type changes of the calcium carbonate and and crystal growth inhibition are for the reason that the BF-30a adsorbs in the crystallization or that the calcium ions on the calcium carbonate crystal interface, with the effect of the chelation, occupy the lattice position for the normal growth of the crystal, which make the crystal cannot normally grow. It is to say that the crystal distortion takes place.

(3) Peptization

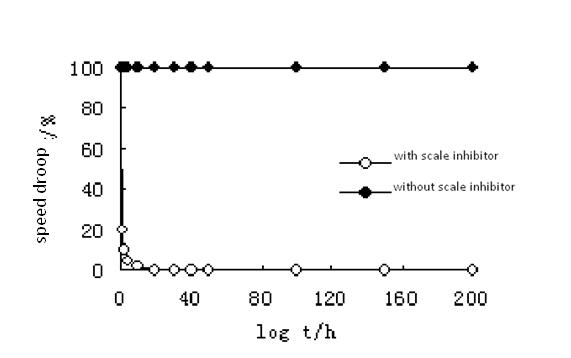

1) Turbidimeter measures the peptization of the BF-30a for the scale in the boiler (Figure 5). The results show that with the absence of the scale inhibitors, the scale in suspension subsides at a faster speed; the turbidity of the supernatant drops significantly and the supernatant within 20h is almost identical with the supernatant without scale. When the supernatant with BF-30a, during the test, the scale keeps in suspension; the turbidity of the supernatant is almost same. Therefore, the BF-30a can make the solids flowing into the boiler with the feedwater or generated in the boiler dispersing in the boiler to prevent the deposition in the heat transfer surface and slow-moving parts. The results also show that this peptization is also non-stoichiometric.

2)

The possible reasons for this peptization is that the BF-30a adsorbs to the surface of the solid particles through the physical and chemical actions and make the particle surface with double layers of electricity, changing the charge state of the particle surface. Under the electrostatic interaction, the particles are mutually exclusive to avoid the particles combining with each other into a deposition, so that the particles remain dispersed in the water.

Figure 5--- Peptization of the BF-30a for the scale

(4) Low-dose effects

The chelation, peptization and the lattice distortion of the BF-30a for the scale are non-stoichiometric. The BF-30a can make the calcium ions more than the amount required by the stoichiometric value stable in the water. It means that the BF-30a has the obvious threshold effect. Therefore, when adopt the BF-30a for anti-corrosion and scaleinhibition, as long as the dosage reaches a certain value or more, the BF-30a can control crystalline growth of the scale ion and show the efficient scale inhibition. And there is no need to add more scale inhibitor than the recommended dosage.

4. The advantages of the technology

BF-30a technology has brought the significant benefits such as saving water and energy, saving equipment investment, extending working life, improving the effectiveness of the heating quality and protecting the environment. A large number of performance testing and the application tests of the water boiler prove the characters that this technology differs from the existing technology as followings:

(1) Effectiveness: When the boiler is in the general conditions, the inhibition rate and the scale inhibition rate of the BF-30a for the boiler both are more than 99%, much better than the rates of the existing similar technology, which solves the corrosion problem of the water boiler.

(2) Convenience: When adopt the BF-30a, it need not to run the deaerator operations, softening operations and sophisticated analysis operations. Also it does not need to operate the drainage, dry the boiler, run the regular analysis and replace the drugs. Just operate the chemical dosing according to the requirements;

(3) Consecutiveness: This technology break through the traditional mode of separately dealing with the boiler in operation or in discontinuation. Regardless of the periods of the boiler for operation or discontinuation, the BF-30a can provide continuous long-term effect for anticorrosive and scale inhibition;

(4) Low price: It does not require the expensive deaerator as the investment; it does not need to change the drugs for the boiler operation or the boiler discontinuation. Thus it can save the cost of the boiler application greatly.

5.Comparison among the similar products and benefit analysis

Currently, the anticorrosive and scale inhibition methods of the most advanced water boiler system still are softening, deaerator and oxygen scavenger methods. Here are the comparisons among these methods. (Refer to the table below):

Comparison item |

Comparison content |

Softening |

Deaerator |

Deoxidants |

Combination |

Inhibition rate |

Calcium and magnesium scale |

99 |

99 |

99 |

99 |

Corrosion products |

0 |

30~99 |

30~99 |

99 |

|

Inhibiting rate |

Boiler in operation |

<0 |

50~99 |

60~99 |

99 |

Boiler in discontinuation |

<0 |

0 |

50 |

99 |

|

Performance( |

Exchanging operation |

O |

O |

O |

- |

Regeneration operation |

O |

O |

O |

- |

|

Deaerator operation |

- |

O |

- |

- |

|

Exchanging analysis |

O |

O |

O |

- |

|

Feedwater analysis |

O |

O |

O |

O |

|

Boiler water analysis |

O |

O |

O |

O |

|

Dosing operation |

- |

- |

O |

O |

|

Drainage operation |

O |

O |

O |

- |

|

Firing boiler operation |

O |

O |

O |

- |

|

Protection operation |

O |

O |

O |

- |

|

Boiling operation |

O |

O |

O |

- |

|

Environmental pollution( O represents “have”, while – represents “have no”) |

Waste brine |

O |

O |

O |

- |

Boiled water |

O |

O |

O |

- |

|

Operation flushing |

O |

O |

O |

- |

|

Discontinuation flushing |

O |

O |

O |

- |

|

Annual cost |

Relative costs |

5 |

7.04 |

5.68 |

1 |

6. The application of the BF-30a boiler anticorrosion scale inhibitor

(1) Application: Mainly used for anticorrosion scale inhibition of the water boiler, water boiler heating system, secondary hot water heating systems with heat exchanger, and low pressure steam boiler.

(2) Main ingredients: the PESA ,HPMA ,ATMP ,corrosion inhibitors M, sodium carbonate, sodium nitrate.

(3) Technical data: scale inhibition rate ≥ 99% ; Inhibiting rate ≥ 99% ; Inhibiting rate for discontinuation protection≥ 99%;

(4) Physical and chemical properties: Alkaline gray solid powder.

(5) Usage: dose the drugs manually or install the automatic water quality monitoring equipment to dose automatically.

(6) Dosage for the water boiler: The initial dosage: 400~600g/T. Dosage for the feed water: 300~500g/T.

(7) Dosage for the steam boiler: The initial dosage: 2000g/T. The dosage for the feed water: 200g/T

(8) Treatment before dosing: Bf-30a adopts the chelation with the slow acting force and scale dissolving function. Generally, directly dose the drugs if the thickness of the scale is less than 2 mm. Otherwise, carry out the chemical cleaning and passivation before dosing to ensure the effect of the drug.

(9) Dosing and monitoring:Small systemsInitial dosing: Estimate maximum water capacity, and then calculate the initial dosage. Dissolve the drug firstly by infusing the water into a container and then adding the solid BF-30a in a certain amount, which can make into the solution with the weight ratio less than 10%. After stirring the solution, pour the solution into the softening tank and get into the boiler system through the feed pump. Because the low temperature of the water in the water boiler, the water in general is not in the saturated state and is in evaporation and concentration without water. The feed water amount for the system is not large, only about 5% of the system water amount. So the initial dosing for the water boiler system before operation plays an important role for the anticorrosion and descaling. So the initial dosage should be more than the dosage for the operation. After the initial dosing, keep the system water pH more than 10.5.

(10) Dosing for the operation: During the operation of the boiler, dose the drugs according to the dosage calculated by the formula that the feed water amount for the water tank every time or every day* dosage for the operation feeding water.

(11) Operation monitoring: Adopt the precise pH test strips to test the system water for every 2 hours. Adjust the solution concentration or the dosage timely to keep the concentration qualified and to keep the pH no less than 10.5. Keep the pH between 10.5 ~ 12 during operation.

(12) Large system: Because of the change of the water capacity, feed water amount and dosage, the manual dosing cannot ensure the concentration and the effect of the BF-30a as required. So the steam boiler with the output that is more than 4t/h and the water boiler with the output that is more than 6 t /h should be mounted with the BGK automatic monitoring equipment.The BGK automatic water quality monitoring equipment can monitor the concentration of the solution continuously and control the dosing equipment automatically dose the drugs to the system in the method of closed loop feedback, which can dose the drug accurately, ensure the using effects, as well as it is equipped with the alternative communication function.The dissolution of the solid drug for the large system and the store of the solution require remolding the original salt pond to ensure the dosage requirement of the system.

7. Equipment inspection

In order to ensure the water treatment effect and the safe operation of the equipment, inspect the equipment periodically: every week, calibrate electrode (refer to the instructions). Check the electrical control, gauge reading and the pump pressure of the equipment every day.

(1) Discontinuation protection

Before the discontinuation of the boiler, replenish the drugs into the boiler and system to make the system water pH more than 10.5. Then close the boiler and system.

(2) Announcements

a. Because of the different water qualities of the different areas, after the recommended dosage, test the pH of the water in boiler frequently. Adjust the dosage according to the actual situation to keep the pH of the boiler water and system water between 10~12.

b. Before the operation of the boiler, adjust the initial dosage to ensure the drug concentration of the solution qualified (pH≥10.5). Then operate the boiler or the system.

c. If the dissolving tank is home-made or is made by remolding the salt pond, sometimes, because of the over-dosing or short stirring time, there will be in the bottom of the dissolving tank. Reduce the concentration of the solution, lengthen the stirring time or add warm water periodically into tank to dissolve the sediment. Otherwise the accumulation of the sediment will damage the dosing pump and then reduce the anticorrosion and descaling effects of the drug.